## Oil Skimmers: Unsung Heroes of Environmental Protection and Industrial Efficiency

In a world increasingly focused on sustainability and resource management, the often-overlooked oil skimmer plays a vital, albeit understated, role. These ingenious devices are the unsung heroes of environmental protection and industrial efficiency, quietly working to remove unwanted oil, grease, and other hydrocarbons from water surfaces.

**What are Oil Skimmers and How Do They Work?**

Oil skimmers are relatively simple machines designed to separate oil from water. They leverage the fundamental principle that oil and water don’t mix, and that oil typically floats on water. Different types of skimmers exist, each with its own strengths and suitable applications:

* **Belt Skimmers:** These use a continuous moving belt, often made of steel or plastic, that passes through the oil-contaminated water. Oil adheres to the belt and is then scraped off into a collection tank.

* **Disc Skimmers:** Similar to belt skimmers, disc skimmers utilize rotating discs that attract oil. The collected oil is then removed with wipers or scrapers.

* **Tube Skimmers:** A flexible tube floats on the water surface, attracting oil. As the tube moves through the water, oil adheres to its surface and is then squeezed or scraped off.

* **Weir Skimmers:** These use an adjustable weir (a barrier) that allows the oil layer to flow over it into a collection tank. They are particularly effective for removing thick layers of oil.

* **Mop Skimmers:** These employ a continuous loop of absorbent material, like a mop head, to soak up oil. The material is then squeezed to extract the collected oil.

**Why are Oil Skimmers Important?**

The benefits of using oil skimmers are multifaceted and impact both the environment and industrial operations:

* **Environmental Protection:** Oil spills, whether large-scale disasters or smaller industrial leaks, can devastate ecosystems. Oil skimmers are crucial for mitigating the impact of these spills by removing oil from water bodies, preventing further contamination of water sources, and protecting wildlife.

* **Wastewater Treatment:** In industrial settings, wastewater often contains oil and grease. Oil skimmers are used as a pre-treatment step to remove these contaminants before the water is discharged or further treated. This reduces the load on downstream treatment systems and helps comply with environmental regulations.

* **Coolant Recovery:** Machining operations often use coolants to lubricate and cool tools. These coolants can become contaminated with oil from the machinery. Oil skimmers are used to remove the oil, extending the life of the coolant and reducing disposal costs.

* **Improved Workplace Safety:** Oil spills can create slippery and hazardous working conditions. By removing oil from floors and surfaces, oil skimmers help to improve workplace safety and reduce the risk of accidents.

* **Resource Recovery:** In some cases, the recovered oil can be recycled or reused, reducing waste and generating cost savings.

**Applications Across Industries:**

Oil skimmers are used in a wide range of industries, including:

* **Manufacturing:** Machining, metalworking, and automotive industries use skimmers to remove oil from coolants and wastewater.

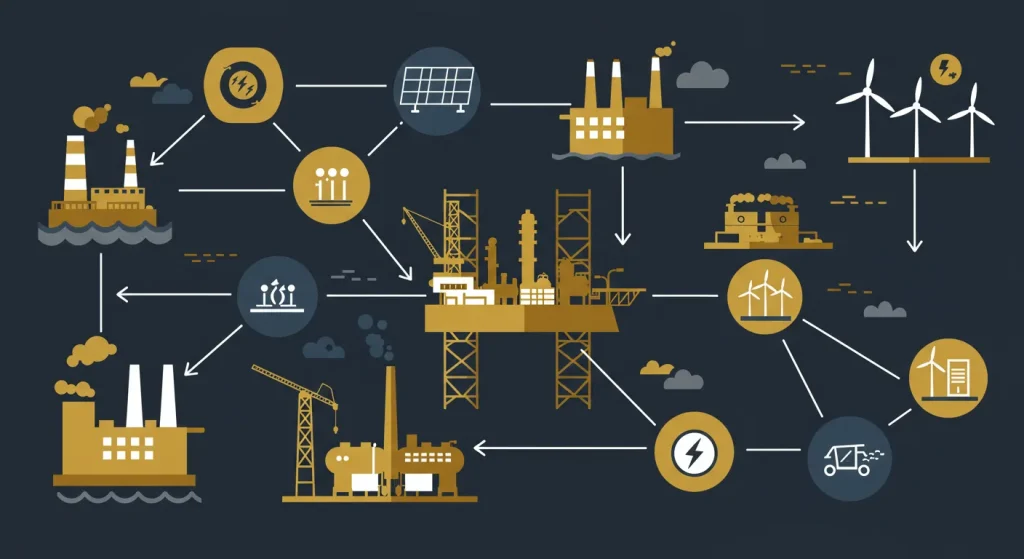

* **Oil and Gas:** Refineries, pipelines, and offshore platforms utilize skimmers to clean up spills and treat wastewater.

* **Wastewater Treatment Plants:** Skimmers are used as a pre-treatment step to remove oil and grease from incoming wastewater.

* **Food Processing:** Food processing plants use skimmers to remove oil and grease from wastewater generated during production.

* **Transportation:** Airports, seaports, and rail yards use skimmers to clean up spills and prevent oil from entering waterways.

**Choosing the Right Oil Skimmer:**

Selecting the right oil skimmer depends on several factors, including the type and amount of oil to be removed, the size and shape of the water body, and the specific application. Considerations include:

* **Oil Type:** Different skimmers are better suited for different types of oil, such as light oils, heavy oils, or emulsified oils.

* **Water Conditions:** Factors like water temperature, pH, and the presence of debris can affect skimmer performance.

* **Flow Rate:** The flow rate of the water body and the desired removal rate will influence the size and capacity of the skimmer.

* **Accessibility:** The accessibility of the water body will determine the type of skimmer that can be deployed.

**The Future of Oil Skimmers:**

As environmental awareness continues to grow, the demand for efficient and effective oil skimming technologies will only increase. Future developments may include:

* **More efficient and selective materials:** Research is ongoing to develop materials that are more effective at attracting oil and repelling water.

* **Smart skimmers:** Integration of sensors and data analytics to optimize skimmer performance and automate operation.

* **Portable and autonomous skimmers:** Development of smaller, more portable skimmers that can be deployed quickly and easily in remote locations.

**Conclusion:**

Oil skimmers are essential tools for protecting the environment and improving industrial efficiency. While they may not be the most glamorous technology, their contribution to a cleaner and more sustainable future is undeniable. By understanding the different types of skimmers available and their applications, we can better utilize these unsung heroes to mitigate oil pollution and conserve valuable resources. As technology evolves, oil skimmers will continue to play a vital role in safeguarding our planet for generations to come.